Crow's been stamping out bubble caps in Houston so long that . . .

. . . The Astros were still called the Colt .45s.

What this means for you is that veteran press operators, with 53 years of hindsight, stamp out your repeatable parts every day.

Stamping Capabilities

- Do you need your sheet metal run through a Progressive die? Want it blanked, formed, or shaped by a cut off production process? Done.

- Want your work deep drawn up to 18", with a 30" circumference? Done.

- Have light or heavy gauge, heavy plate, or intricate metal work? Done.

- Need access to coil fed presses up to 500 tons? With speeds of 90 strokes/min? Done.

- How about press bed dimensions to 120"L x 48"W? Need 3" to 18" press strokes? Done and Done.

Material Types

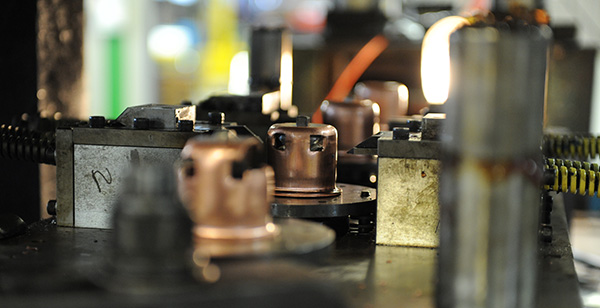

Your high quality metal stampings come in:

- aluminum

- copper

- titanium

- carbon

- stainless steels

Thicknesses vary up to 0.5" with sizes to 200"L x 12" W.

Press Operators

The standard tolerances for our pressmen are ±.015. Yes, our stamping operations are fully supported by a team of press professionals with decades of experience individually, to ensure high efficiency and best quality.

Quality

Your work passes through a "distillation tower" of testing and quality control protocols--before ever leaving our floor.

Typical lead times are 7 to 10 business days, with rush service available.

Industries Served

For 5-decades Crow's metal stamping services have been the bread and butter for industries such as:

- Petrochemical

- Oil & Gas

- Alternative energy

- Offshore

- Medical

- Construction

Finish your parts up with a tin, powder or phosphate coating--galvanize your work, sand blast, or wet paint all of it.

So if you have a line of redundant stampings you'd like to run through a competent press room,

Then please request a quote online, or contact the Director of Sales at (281) 357-4600.

" With big data, instead of precisely understanding why an engine breaks down or why a drug’s side effect disappears, researchers can instead collect and analyze massive quantities of information…Big data helps answer what, not why, and often that’s good enough…The possession of knowledge, which once meant an understanding of the past, is coming to mean an ability to predict the future."--Kenneth & Viktor Mayer-Schoenberger, (2013, May/June), The Rise of Big Data. Foreign Affairs, 29, 39

| Production Method | |

|---|---|

|

|

| Production Capabilities | |

|

|

| Materials | |

|

|

| Inspection | |

|

|

| Testing | |

|

|

| Quality Control | |

|

|

| Additional Services Provided | |

|

|

| Secondary Finishes | |

|

|

| Production Volume | |

|

|

| Typical Lead Times | |

|

|

| Industry Focus | |

|

|

| Possible Applications | |

|

|

| Industry Standards | |

|

|

| File Formats | |

|

|