Stack fixtures to wire your parts faster

Need Crow to do a rework for you on some of your previously incomplete parts?

How about 61 of these keyways, cut all the way through, in a week's time? One Crow customer did.

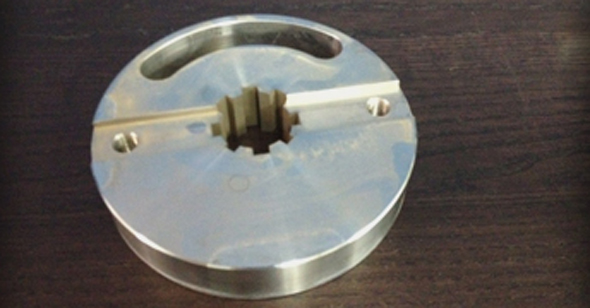

And they provided Crow with a pre-made fixture to help with their rotator bases. But the fixture supplied could only wire one piece at a time.

So Crow’s EDM Department went to the drawing board.

They thought, "How can we speed up this rework on the wire?"

"Voila! Let's make a couple more fixtures and EDM four at a time!"

Then with fixture on top of fixture, on top of fixture, a total of 12 rotator bases ran through the wire complete at one time.

Additionally the customer sent us 61 pre-bored holes, but wanted the holes opened up some more. So with an exact CNC setting, Crow was able to yawn out the geometrically complex splines inside the holes.

Just in time,

And featuring dimensions of 1.0" in height, an outer diameter of 5.00", and weighing 5 lbs., this part was machined to within the very tight ± 0.005" dimensional and ± 1° angular tolerances.

The part was also marked according to the customer's specification, and went through systematic inspections to ensure that the highest quality level had been maintained.

The agility and fast-paced operations gave the customer what he wanted: a complete job with superior quality and a burr-free surface finish, in less than one week.

So for your overcomplicated parts, which may require a Wire, contact Crow Corporation today.

Wire EDM Capabilities Applied/Processes |

|

||

Equipment Used to Manufacture Part |

Wire EDM |

||

Overall Part Dimensions |

OD: Ø 5.00" |

||

Tightest Tolerances |

± 0.005" |

||

Material Used |

316 Stainless Steel |

||

In process testing/inspection performed |

Dimensional Inspection, Visual Inspection |

||

Volume |

61 |

||

Delivery/Turnaround Time |

5 work days |

||

Delivery Location |

Anywhere |

||

Standards Met |

Customer Specifications, 2D CAD Drawing |