Distribute power midstream in your flow

Built for the pipeline industry this poll-mounting hardware serves as the energy source through multiple power lines.

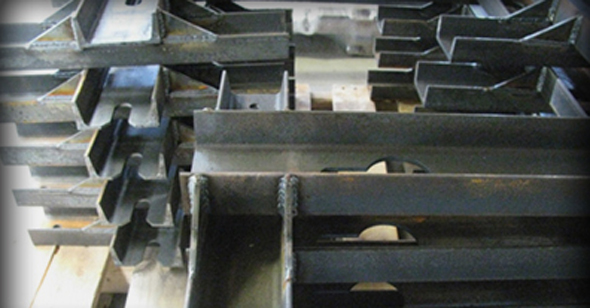

Manufactured from rolled steel with uncrackable, antifatigable fab work, Crow's certified MIG men finished'em up with defect-free welds.

The assemblies were also sandblasted for cleanliness and hot dip gavanized to be corrosion resistant.

So with decades of experience to meet your pipeline energy needs, whether coal or nuclear, tight-tolerance component welding skills are present here on the Crow shop floor.

Want to save time and money with this work?

Then think single vendor.

Think Crow's weld & fab shop.

So join your steel with good welds and contact us today.

Product Description |

Welding Sub-Assembly |

||

MIG Welding Capabilities Applied/Processes |

|

||

Overall Part Dimensions |

Length: 565mm |

||

Tightest Tolerances |

± 0.1mm |

||

Material Used |

Rolled Steel |

||

Material Finish |

Hot Dip Galvanized |

||

In process testing/inspection performed |

Dimensional Inspection, Visual Inspection |

||

Industry for Use |

Big pipe |

||

Volume |

15 |

||

Delivery/Turnaround Time |

30-60 days |

||

Standards Met |

Customer Specifications, 2D CAD Drawing |